Biological Safety Cabinets and Laminar Flow Cabinets

A Biological Safety Cabinet (BSC) is a ventilated cabinet that uses a combination of High-Efficiency Particulate Air (HEPA) filtration, laminar airflow, and containment to provide personnel, product, and environmental protection from biohazardous agents. This is achieved by air intake and recirculation that is filtered prior to exhausting to the cabinet exterior. All work with potentially infectious agents should be completed inside of a biological safety cabinet.

In addition to ensuring safe BSC practices within laboratories, Auburn University Risk Management and Safety coordinates the certification, relocation, decontamination, and disposal of all biological safety cabinets and laminar flow cabinets on campus.

Types of BSCs

Class I

A Class I biological safety cabinet is defined as a ventilated cabinet for personnel and environmental protection. Class I cabinets do not offer product protection from contamination. They use non-recirculated airflow away from the operator. Class I cabinets have a similar airflow pattern to a fume hood, but they also have a HEPA filter at the exhaust outlet. Class I cabinets are safe for use with agents requiring Biosafety Level 1, 2, or 3 containment.

Class II

A Class II biological safety cabinet is defined as a ventilated cabinet for personnel, product, and environmental protection for microbiological work or sterile pharmacy compounding. Class II BSCs are designed with an open front with inward airflow (personnel protection), downward HEPA-filtered laminar airflow (product protection), and HEPA-filtered exhaust air (environmental protection). These cabinets are further differentiated by types based on construction, airflow, and exhaust systems. The types include A1, A2, B1, B2, and C1. Like Class I cabinets, Class II cabinets are safe for work using agents requiring Biosafety Level 1, 2, or 3 containment.

The most common type of BSC at Auburn University is a Class II/A2 cabinet.

Class III

A Class III biological safety cabinet (also called a glove box) is defined as a totally enclosed, ventilated cabinet with leak-tight construction and attached rubber gloves for performing operations in the cabinet. The cabinet has a transfer chamber that allows for sterilizing materials before they leave the glove box. The cabinet is maintained under negative pressure and supply air is drawn in through HEPA filters. The exhaust air is treated with either double HEPA filtration or HEPA filtration and incineration. Class III cabinets are safe for work requiring Biosafety Level 1, 2, 3, or 4 containment.

Laminar Flow Cabinets (LFCs)

A laminar flow cabinet or laminar flow hood or clean bench is a carefully enclosed bench designed to prevent contamination of research materials such as semiconductor wafers, biological samples, or any particle-sensitive device. Air is drawn through a HEPA filter and blown in a smooth, laminar flow towards the user or towards the work surface. The cabinet is usually made of stainless steel with no gaps or joints where spores may collect.

Laminar flow cabinets are different from biological safety cabinets in that they provide product protection ONLY by either providing a horizontal or vertical positive pressure flow air environment.

Laminar flow cabinets do not provide personnel or environmental protection. The horizontal flow clean benches are used in clinical, pharmaceutical, and laboratory facilities without toxic, infectious, radioactive, or sensitizing materials. The vertical flow clean benches are useful for certain manipulations of clean materials (e.g., pouring agar plates, etc.). Therefore, LFCs should only be used to provide a sterile environment and never for work with infectious/biohazardous materials.

Preparing for Work Inside the BSC

Factors Affecting BSC Airflow

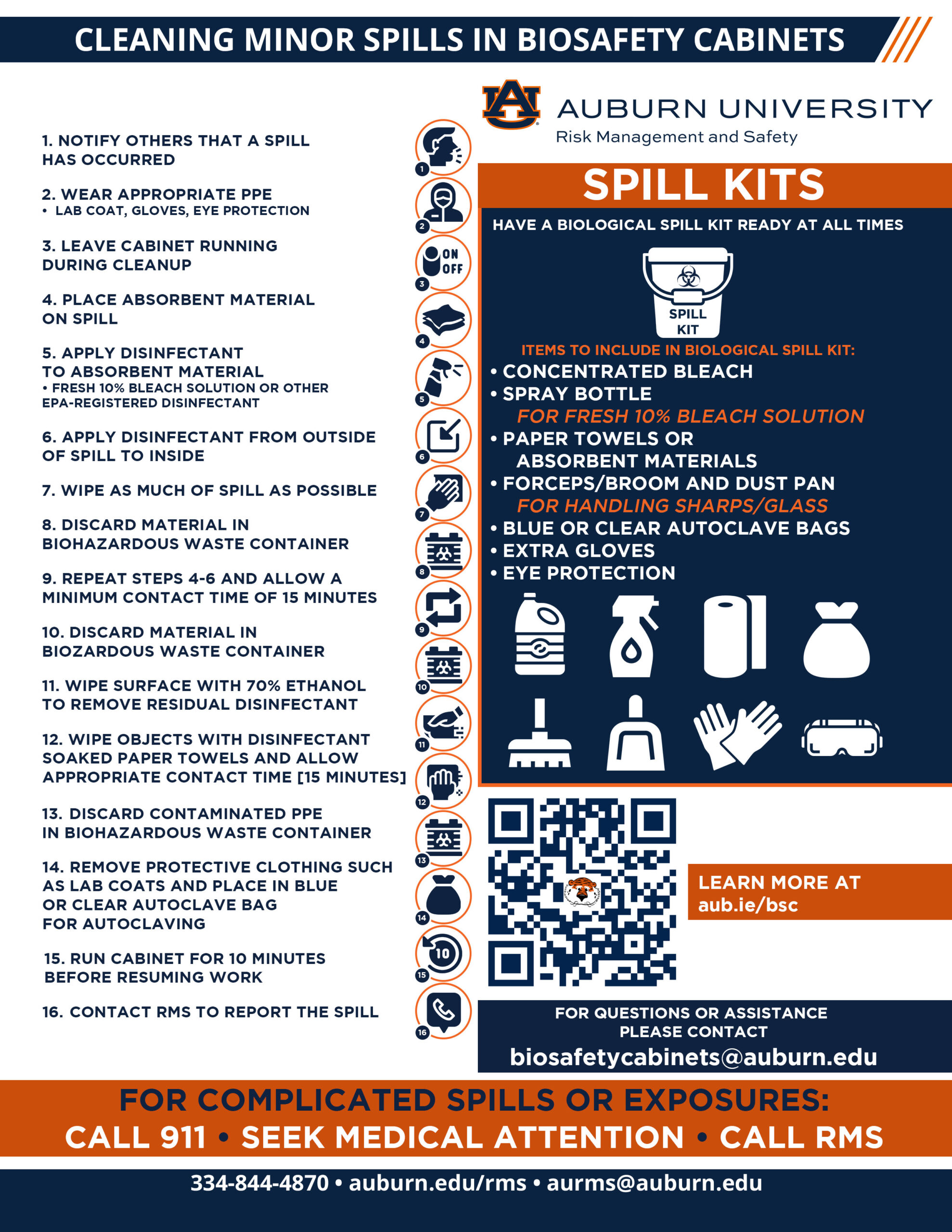

Cleaning Spills in a Biological Safety Cabinet

Certification for BSCs and LFCs

All biological safety cabinets are required to have an annual inspection and certification if used for primary containment and personal protection against biohazards. This annual inspection assures proper cabinet operation and capability in accordance with the manufacturer’s specifications and/or the National Sanitation Foundation (NSF) 49 Standard. It is also recommended that all laminar flow cabinets or “clean benches” be certified annually to assure product protection capability.

Risk Management and Safety coordinates with a preferred vendor (Safety Plus, LLC) twice a year to certify all the cabinets on campus, as well as any time in between for decontamination and recertification needs. All certification costs are the responsibility of the requesting department and payment processing is managed by RMS.

All cabinets must be certified when installed, relocated, or upon completion of major repairs.

If your cabinet is in need of certification, please contact Jessica Powell (334-707-2835 or jap0057@auburn.edu).

Relocation of Biological Safety Cabinet

Biological safety cabinet relocation is coordinated with AU Facilities Campus Moving Services and Risk Management and Safety.

BSCs must be decontaminated prior to relocation and recertified after relocation before they can be used again.

If a cabinet is to be relocated to an Auburn University laboratory from another institution, documentation will be required by the biological safety officer to prove decontamination at the previous location before the cabinet can be moved to Auburn. The cabinet will need to be recertified by Safety Plus once it is installed in the Auburn laboratory.

Please contact Jessica Powell (334-707-2835 or jap0057@auburn.edu) for the relocation of a biological safety cabinet.

Disposal of a Biological Safety Cabinet

A laminar flow cabinet or laminar flow hood or clean bench is a carefully enclosed bench designed to prevent contamination of research materials such as semiconductor wafers, biological samples, or any particle-sensitive device. Air is drawn through a HEPA filter and blown in a smooth, laminar flow towards the user or towards the work surface. The cabinet is usually made of stainless steel with no gaps or joints where spores may collect.

Laminar flow cabinets are different from biological safety cabinets in that they provide product protection ONLY by either providing a horizontal or vertical positive pressure flow air environment.

Laminar flow cabinets do not provide personnel or environmental protection. The horizontal flow clean benches are used in clinical, pharmaceutical, and laboratory facilities without toxic, infectious, radioactive, or sensitizing materials. The vertical flow clean benches are useful for certain manipulations of clean materials (e.g., pouring agar plates, etc.). Therefore, LFCs should only be used to provide a sterile environment and never for work with infectious/biohazardous materials.

For Questions about BSCs or LFCs:

Deepika Suresh